|

|

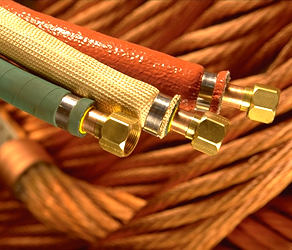

Flexible power cables

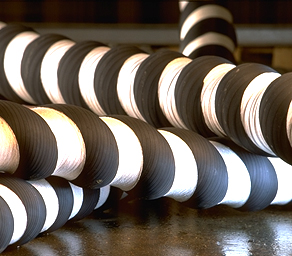

Nu-Core custom builds the most innovative, long lasting power cables for today's industries requiring high-current electrical needs. We build and repair each cable to meet your exact specifications, with extended operating life as our primary goal. Nu-Core designs and builds a wide variety of water-cooled flexible power cables used for many types of applications. We build and repair small power leads for small induction furnaces to the world's largest cables used in electric arc furnaces and other high current specialty applications. Whether the smallest or the largest cables, our goal is the same: to make your cables perform to their optimum specifications for as long as possible. Because avoiding down time is critical to your operation, the people at Nu-Core are available day and night, 365 days a year, to respond to your flexible power cable needs. We stock and maintain an extensive inventory of terminals, copper wire and hose coverings to ensure you receive a quality product in the shortest time possible. You can cut your costs by sending us your damaged cables for repair. We repair all brands to meet or exceed original specifications, regardless of the original equipment manufacturer (OEM). High Current Water-Cooled Cables Nu-Core builds and repairs each flexible power cable to meet your precise specifications, with extended operating life as our primary goal. We engineer special features such as flexible riser tubes and bend restrictors installed behind the terminal to reduce copper wire failure at major stress points. Nu-Core's protective outer hose, made from a high-dielectric strength non-conductive compound, withstands severe pressures, abrasion and high temperatures while retaining flexibility. We offer a variety of additional hose coverings for severe abrasion and extreme high temperature applications. Induction and Vacuum Furnace Water-Cooled Cables At Nu-Core, we build the same quality and engineering into our induction and vacuum furnace cables that we do in our larger ultra-high current cables. We manufacture our cable terminals using one solid piece of high-conductivity copper. Our cables are also made with soft drawn copper rope, stainless steel bands and a variety of hose coverings for different operating environments. In most cases we ship your new or repaired cables before noon the next day. If we receive your order before noon, you can usually count on same day shipment. Air Cooled Cables and Jumpers |

|